Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

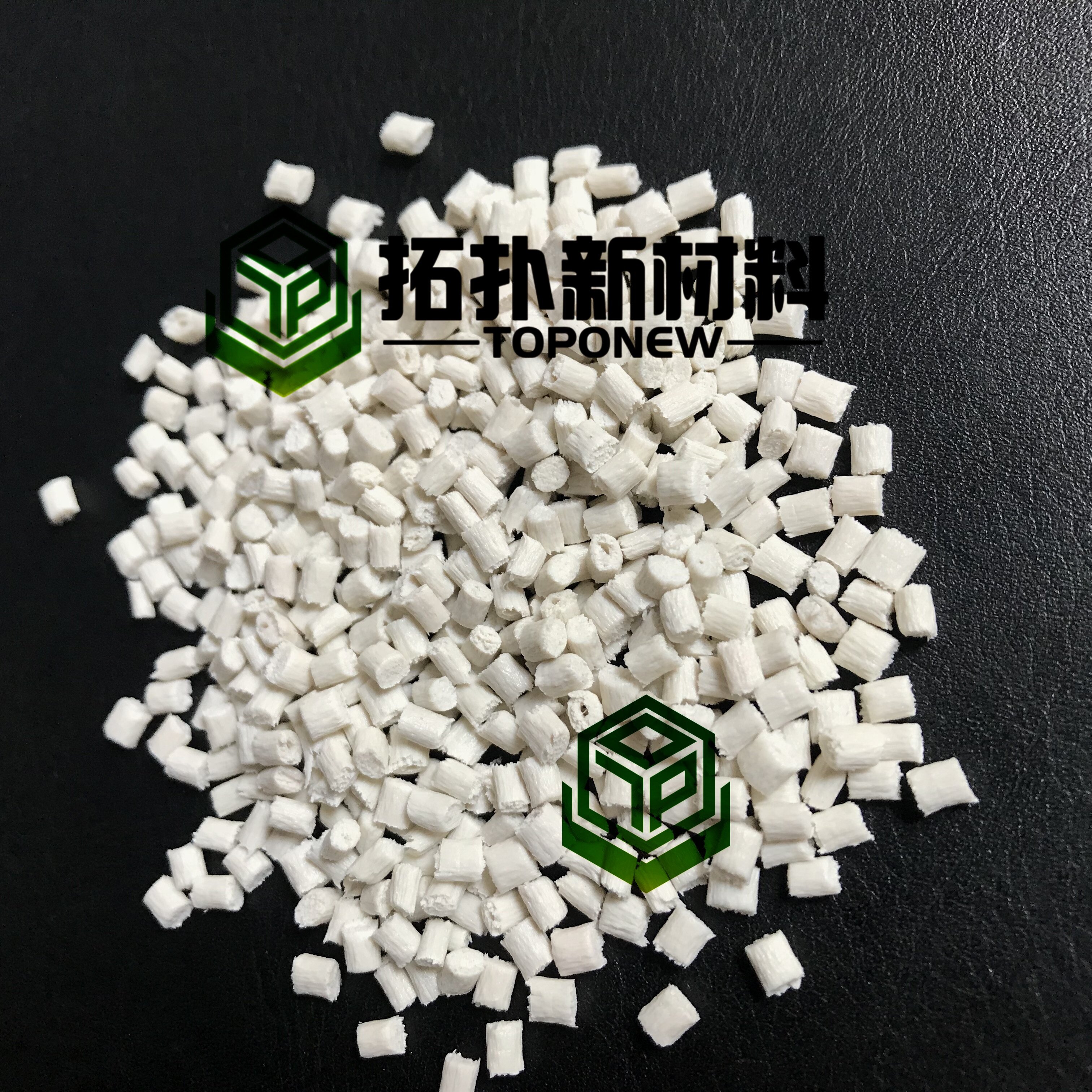

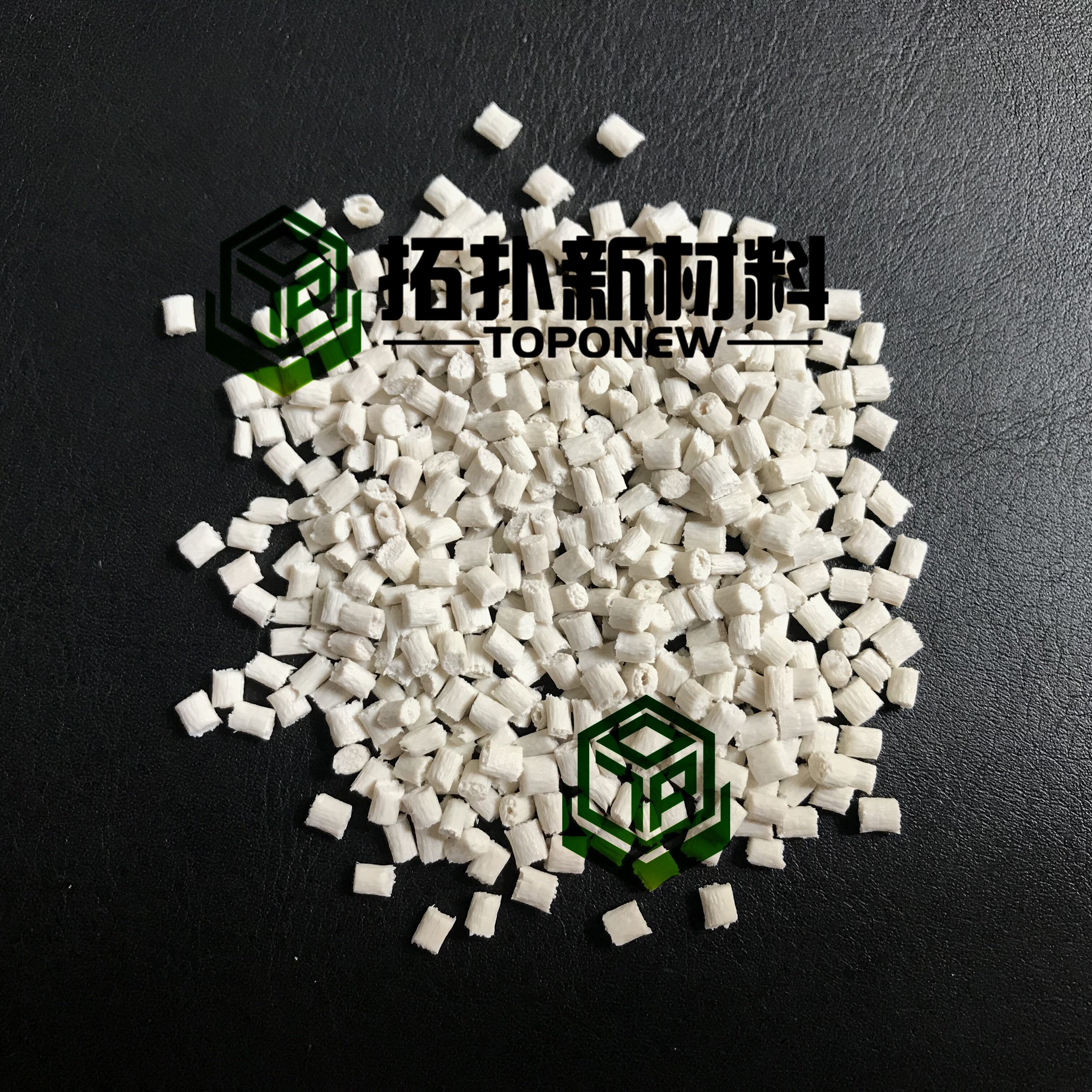

PA6 TPMC4000

Toughened PA6

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Nylon 6, also known as PA6, is a versatile engineering plastic with numerous uses. It finds its application in the manufacturing of textiles, automotive parts, electrical connectors, gears, bearings, and many more. Its exceptional strength and durability make it an ideal choice for demanding applications where toughness and resistance to wear and tear are crucial.

Now, let's explore the meaning behind the "6" in nylon 6. The "6" represents the number of carbon atoms found in the material's monomer, caprolactam. Nylon 6 is created through a polymerization process, where six carbon atoms combine to form a long chain structure. This process gives nylon 6 its unique properties, including excellent tensile strength, heat resistance, and chemical resistance.

Nylon 6 pellets are the result of transforming nylon 6 raw materials into a pelletized form. These pellets serve as the feedstock for injection molding processes, where they are melted and injected into molds to create various products with intricate shapes and structures. The pellet form of nylon 6 offers convenience in handling, transportation, and processing, making it an efficient choice for manufacturers.

As one of the top nylon 6 manufacturers, TOPONEW understands the importance of sourcing high-quality nylon 6 raw materials. We work closely with trusted suppliers to ensure that we obtain the best raw materials for our plastic granules. Our team of experts carefully selects and processes the raw materials to deliver consistent and reliable PA6 plastic granules, specifically designed for injection molding applications.

At TOPONEW, we specialize in providing plastic granules for injection molding. Our PA6 plastic granules are precisely engineered to meet the demanding requirements of the injection molding process, ensuring excellent flowability, moldability, and overall product quality. Whether you need plastic granules for automotive parts, consumer goods, or industrial components, we have the expertise and resources to meet your specific needs.

Partner with TOPONEW and let us be your reliable supplier of top-quality plastic granules for injection molding. Contact us today to discuss your requirements and discover how our expertise can contribute to the success of your projects.

The Characteristics of Toughened Nylon 6 PA6 TPMC4000

High strength: Toughened nylon 6 exhibits excellent mechanical properties, including high strength and stiffness, allowing it to withstand heavy loads.

Impact resistance: This material has improved impact resistance compared to traditional nylon 6, making it more resistant to cracks and fractures under dynamic loads.

Enhanced toughness: Toughened nylon 6 exhibits enhanced toughness and resistance to breakage, making it suitable for applications requiring durability and resistance to deformation.

Good chemical resistance: It has good resistance to various chemicals, oils, and solvents, ensuring its suitability for use in harsh environments.

Wear resistance: Toughened nylon 6 possesses good wear resistance, allowing it to withstand friction and abrasion, making it suitable for applications where components are subjected to constant rubbing or sliding.

Easy to process: It is relatively easy to process and mold into complex shapes, providing versatility in manufacturing and design flexibility.

Toughened Nylon 6 finds application:

Automotive industry: Toughened Nylon 6 is used to manufacture car parts such as engine covers, car housings, and intake pipes. Its high strength and impact resistance allow it to withstand vehicle vibrations and external impacts, while maintaining good wear resistance and chemical stability.

Electronics: This material has wide applications in electronic products such as cable fixtures, sockets, connectors, and switches. Its mechanical strength and durability enable it to withstand physical pressure and wear in daily use.

Industrial equipment: Toughened Nylon 6 is also utilized in industrial equipment for components like gears, bearings, and mechanical parts. Its strength and toughness make it suitable for demanding industrial environments.

Consumer goods: Toughened Nylon 6 is used in the manufacturing of various consumer products, including sporting goods, household appliances, and tool handles. Its combination of strength, durability, and chemical resistance makes it a versatile choice.

Overall, Toughened Nylon 6 offers a balance of mechanical properties and durability, making it suitable for a wide range of applications across different industries.

Related PA6 material:

https://www.toponew.com/products/pa6-compound/PA6-E070830WL

https://www.toponew.com/products/pa6-compound/pa6-gf50-e0750

Download

-

PA6 TPMC4000.pdf

Download PA6 TPMC4000.pdf